The clean energy revolution, despite recent policy developments, is upon us. The Netherlands' main train company now runs entirely on wind energy. Electric cars are making inroads, especially in high density urban areas.

But, to be frank, batteries are not a great replacement for hydrocarbons: their energy density is relatively low, and recharging times are rather long. Despite it being irrational for most people, range anxiety is a real thing for some.

This is where solar fuels could provide a solution—a transportable fuel generated using nothing but sunlight. But production of solar fuels is a tediously inefficient process, since the generation of electricity and production of fuel have to be done separately. Avoiding that separation is why a new form of solar cell that performs electrolysis (splitting water into hydrogen and oxygen) directly may be the future.

Solar fuels?

There are many approaches to solar fuels: react carbon dioxide with water to produce hydrocarbons and less water. Another approach is to crack water to make hydrogen and oxygen. The hydrogen can be used directly or reacted with carbon dioxide (or carbon monoxide) to create hydrocarbons. In either case, the energy used to drive the processes is renewable, so you end up with carbon-neutral fuel. And, if you make a longish hydrocarbon chain, it will be liquid, which has some serious advantages with respect to storage and transport.

The options that involve carbon dioxide are problematic at the moment. Carbon dioxide needs to be concentrated before the reaction will run efficiently, and it's not energetically favorable. It requires rather high electrode potentials and the transfer of lots of electrons (eight in total, I believe). That makes life tough.

But water is abundant, and the electrode potentials for electrolysis are not as bad. Even better, you only need to transfer two electrons. All in all, it seems that hydrogen production is the most viable path at the moment.

Getting the Sun to do the work

In terms of green energy, the simplest way to split water is to hook a solar cell up to an electrolysis cell and wait. It's not elegant, and there are some inherent inefficiencies in dividing the electron generation and electrolysis parts. An elegant solution would be to have a solar cell that also performs electrolysis.

The big issue with this approach is that most solar cells only have one electrode available. The standard manufacturing process involves depositing one electrode on a supporting wafer. The active material is then deposited on the electrode, and a second electrode that is either transparent or does not completely cover the surface is deposited on top.

Now, if you want to turn this into a solar cell that also splits water, the top electrode also has to act as the catalyst for the reaction—normally a metal like platinum—and be transparent to light. The standard approach is to use very thin electrodes, which let most of the light through.

Or would, if it were only down to the electrode. Unfortunately, when water splits, it creates little gas bubbles that scatter light away from the solar cell. An effective solar cell that splits water will self-limit simply because light cannot reach the solar cell anymore. These two problems can be circumvented by using the back electrode of the solar cell, except manufacturing usually buries this on the interior.

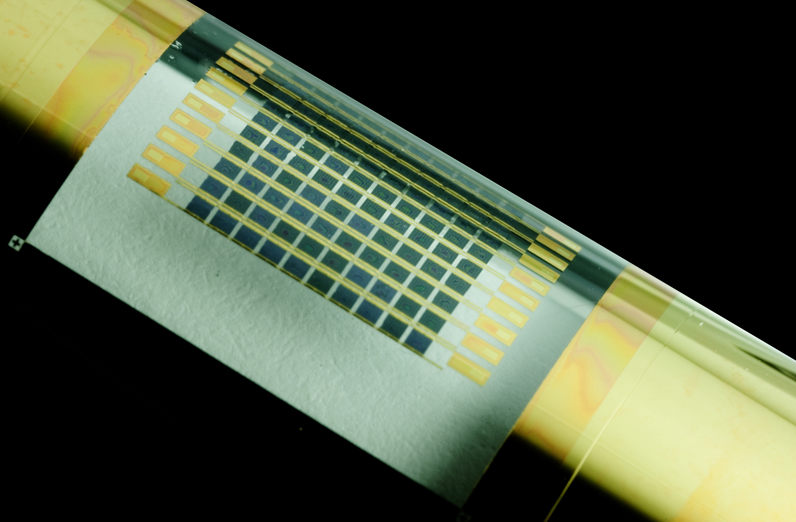

This is where the latest research comes in. The researchers grow gallium arsenide-based solar cells on a gallium arsenide wafer. They then lift the grown layer and electrode from the wafer, making the back electrode accessible. The front is then pressed up against glass to provide physical support.

The researchers showed that the solar cell performance was pretty much unchanged from the more standard approach, with efficiencies around 15 percent. That efficiency is the conversion from light to electricity. In this case, though, we are more interested in how much hydrogen is obtained. Here, the researchers claim an efficiency of 13 percent. That number is kind of meaningless by itself. But, basically, electrolysis requires a certain potential at the electrode and two electrons per reaction. Since the solar cell is operated as an open circuit, the only place electrons can be consumed is by the production of hydrogen. So, a measure of the power consumed by the solar cell, compared to the power incident on the solar cell, is also a measure of the efficiency of hydrogen production.

More importantly, the researchers showed that the thick catalytic electrode protected the solar cell from the chemistry of water splitting. If the solar cell is not protected, the hydrogen leaks into the gallium arsenide and erodes it away. Thin electrodes don't provide much protection against this sort of problem because hydrogen, like sand at the beach, gets everywhere. The only protection is a thick layer of impermeable material.

Silicon still rules on cost

Those efficiency numbers are not the sort that make you shout "ok, we're done here." Gallium arsenide solar cells with much higher electrical efficiencies have been demonstrated (multi-junction cells reach 45 percent). And catalysts with better water splitting properties are available. These have not been combined in this experiment, so there is potential for improvement there.

The big drawback is that gallium arsenide is expensive. This is where the lift-off technique that separates the solar cell from the supporting wafer is a big advantage. The solar cell is removed from the wafer, which can be reused to make a new solar cell. That means that the amount of gallium arsenide per cell is, comparatively, very small. In the case here, the solar cell consisted of a series of gallium arsenide layers that come to a total thickness of 4 to 4.5 micrometers, while the wafer that it is grown on is 250 to 700 micrometers thick, so the amount of material consumed is reduced by about a factor of 100. Considering that these cells have to compete with silicon, which is incredibly cheap, this is an important step, independent of whether the whole water splitting thing works out.

Nature Energy, 2017, DOI: 10.1038/nenergy.2017.43

reader comments

57