Yale celebrates safety culture for 2018 National Forklift Safety Day

In addition to the corporate presence in Washington, Yale dealers will also offer local NFSD events.

As June 12 marks the 5th annual National Forklift Safety Day (NFSD), Yale Materials Handling Corporation is celebrating its year-round investment in safety.

Company representatives will be in Washington, D.C. June 11-12 for the official NFSD events, participating in educational sessions and meeting with congressional representatives on safety, education and workforce.

“The Industrial Truck Association’s National Forklift Safety Day and the National Safety Council’s designation of June as National Safety Month give us an opportunity to spotlight something that’s important to us year-round – safety,” says Chris Murtha, brand manager, Yale Materials Handling Corporation. “Whether it’s industry-wide education, smart equipment features or effective operator training, we are committed to making the materials handling industry safer and more productive.”

In addition to the corporate presence in Washington, Yale dealers will also offer local NFSD events. For example, Barclay Brand Ferdon is welcoming visitors to its third annual Safety Summit in South Plainfield, N.J. For more information and to register for free, click here.

Yale’s commitment to safety is also reflected in safety-enhancing lift truck features. The Yale Smart Operator Sensing System uses detection sensors rather than pedals to reinforce proper operating position while offering more usable floor space and improved comfort. The Continuous Stability System (CSS) is a simple, effective mechanical system built into the fundamental design of the truck, improving stability with no maintenance requirements, sensors, controllers or extra wiring.

The company’s award-winning Yale Handle with Care Operator Training Program draws on 40 years of experience developing professional lift truck operator training. The video-based program covers all five lift truck classes, with necessary tools for customized operator training. Yale also offers pedestrian and forklift safety tip posters that feature best practice checklists based on OSHA regulations. Download for free here.

View Yale Forklifts

Yale MC10-15 Driven by Balyo – counterbalanced robotic lift truck

Yale MC10-15 Driven by Balyo – counterbalanced robotic lift truck

Capable of vertical movement for transferring pallets from floor-level staging areas to conveyor lines, loading and unloading in cross-docking operations or stacking on elevated storage racks.

Yale robotic lift trucks

Yale robotic lift trucks

The benefits of automation are clear – enable labor to focus on higher-value added tasks while increasing operational efficiency, reducing operating costs and minimizing damaged goods and accidents.

Article Topics

Safety News & Resources

A-SAFE officially launches Monoplex Bollard Powerfleet’s newest AI-powered solution meets need for greater pedestrian safety in the warehouse ELOKON introduces safety system for driverless transport vehicles Treston acquires business assets of IAC Industries Improve safety and ergonomics with code-compliant stairs Department of Labor announces national emphasis program aimed at reducing workplace hazards in DCs Sensors give lift truck safety a boost More SafetyLatest in Materials Handling

Beckhoff USA opens new office in Austin, Texas Manhattan Associates selects TeamViewer as partner for warehouse vision picking ASME Foundation wins grant for technical workforce development The (Not So) Secret Weapons: How Key Cabinets and Asset Management Lockers Are Changing Supply Chain Operations MODEX C-Suite Interview with Harold Vanasse: The perfect blend of automation and sustainability Consultant and industry leader John M. Hill passes on at age 86 Registration open for Pack Expo International 2024 More Materials HandlingSubscribe to Materials Handling Magazine

Find out what the world's most innovative companies are doing to improve productivity in their plants and distribution centers.

Start your FREE subscription today.

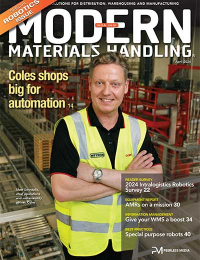

April 2024 Modern Materials Handling

Latest Resources