- India

- International

Workplace Injuries: Rage Against The Machine

Somya Lakhani meets the untrained and under-equipped factory workers who have lost fingers to accidents on the job, and discovers the obstacles on the road to recovery

Ram Pravesh Tiwari, who lost his fingers in an accident while working at a factory in Mayapuri. (Express photo/Tashi Tobgyal)

Ram Pravesh Tiwari, who lost his fingers in an accident while working at a factory in Mayapuri. (Express photo/Tashi Tobgyal)

At 9:20 am, Naresh landed at the Aarah Machine Chowk in Wazirpur industrial area, in one of the two oversized full-sleeve shirts he owns. The 33-year-old looked sharp, his hair neatly parted, shirt tucked in and shoelaces tightly knotted around his ankles.

But the unbuttoned long sleeves of his shirt gave him away. “I am trying to hide my hands by wearing long-sleeve shirts. I don’t have three-and-a-half fingers, so I don’t get picked for factory work… A day at the steel factories here earns Rs 400, but if I don’t get that, I end up taking odd jobs all day and return home with less than half,” he said.

Since he arrived in Delhi in 2012 with his wife and four children, Naresh has lost his fingers in two separate incidents, receiving zero compensation and leaving him with no steady job. His family left for their hometown, Budaun, in January — two months after Naresh lost his left hand’s middle finger while operating the power press machine in one of Wazirpur’s 100-plus steel utensil manufacturing factories.

By 11 am, Naresh knew it’s not his day. “Dil toot gaya hai ab… Yahin kaam kiya, yahin ungliyaan khoyi aur yahin par dehaari nahi kama pa raha hoon (My heart is broken… I lost my fingers doing the same work I can no longer get),” he said, before disappearing into the crowd.

Take a walk through the industrial hubs of Wazirpur and Mayapuri, and the sight of men missing one or more fingers begins to appear almost commonplace. The Indian Express met at least 15 such men, and a woman, over the last two weeks — to discover problems ranging from lack of training and protective gear, no concept of compensation, to a system of redressal which the poor find intimidating, and a parallel system of clinics willing to hush up matters for a price.

“Wazirpur industrial area is a hub of factories manufacturing steel products — stainless steel utensils, grills, pipes, big vessels. Heavy machinery is used, especially the power press machine. Of every 10 labourers who lose their fingers, six fall victim to this machine. It’s the most common disability here… just take a walk and see for yourself,” said Bhaskar, a member of Delhi Ispat (steel) Udyog Mazdoor Union.

Arun Kumar, who worked in Mayapuri. (Express photo/Tashi Tobgyal)

Arun Kumar, who worked in Mayapuri. (Express photo/Tashi Tobgyal)

More often than not, workers who suffer such accidents find themselves quickly replaced. Take, for instance, Kamlesh (50), who lost four fingers of his left hand 10 years ago while working at a steel unit. “Everything changes with that one cut… it’s not an inconvenience; it’s a disability that leaves you jobless, homeless, broke.”

‘What do we do next?’

The most recent reported incident took place on August 10, when Vinod Kumar (28) lost three fingers of his left hand while cleaning a vacuum pump machine fixed inside a septic tank at the CISF camp in Mahipalpur.

“It was a two-day job and I was told how to switch the machine on and off. I was cleaning when someone switched it on, and that was it. The job paid Rs 400 a day. Officials took me to Safdarjung Hospital and left me there,” said Kumar, standing in a queue at the hospital, with two syringes sticking out of his now infected fingers.

Accompanying him was his cousin Susheela. “His hand smells rotten, there are worms on the fingers. We have no money for treatment, the contractor didn’t give a rupee. What do we do next?” she asked.

The answer to this question eludes most.

At Ashok Vihar’s Labour Welfare Office — one of nine in Delhi — sits Anita Rana, commissioner, employees’ compensation. Apart from files of ongoing cases, there is also a copy of the Employees’ Compensation Act 1923 on her desk, which details the process of getting compensation after an injury or death at the workplace.

“We get about 20 cases per month of injuries… electrocution, cut fingers and legs. About half of these cases are of fingers that got cut while operating heavy machinery like the power press machine. Most cases come through trade unions. Workers tell us they are not trained to operate the machines, and are not provided safety gear. We have heard labourers complain about employers removing ‘sensors’ from the machine so it doesn’t slow down. That leads to a lot of accidents,” said Rana.

Another officer said only labourers who do not have Employees’ State Insurance (ESI) can apply for compensation at the office. He said, “We then refer him to a government hospital where a panel decides the percentage of disability. We calculate the compensation according to the wage, age and percentage of the disability, as mentioned in the Employees’ Compensation Act.”

Another problem, IFTU and Delhi Ispat (steel) Udyog Mazdoor Union members said, is that many workers don’t have Employees’ State Insurance (ESI). (Express photo/Somya Lakhani)

Another problem, IFTU and Delhi Ispat (steel) Udyog Mazdoor Union members said, is that many workers don’t have Employees’ State Insurance (ESI). (Express photo/Somya Lakhani)

As per the Act, “loss of two fingers of one hand” is 20% disability; “loss of three fingers of one hand” is 30% disability; and “loss of four fingers of one hand” is 50% disability. Rana said, “Getting compensation in cases of death is easier in a way… Declaration of percentage of disability by the panel of doctors takes a while. In some cases, we do overrule the panel… if the worker puts up a case of having lost his livelihood due to loss of two fingers, we can ask for 100% compensation (from the employer).”

Arun Kumar (25) hopes he falls in this category. Late night on January 1, 2016, his right hand came under the shearing machine, and he lost the top of two fingers. “The person who operated the machine wasn’t there, so I had to. I resisted, but they told me how to switch it on but not how to switch it off, and get to work,” recalled Kumar.

Kumar said he received no compensation, and it took the employer 20 days to pay him his previous wages of Rs 4,800. An FIR was registered, and as per calculations made by Rajesh Kumar, general secretary of the Indian Federation of Trade Unions (IFTU), the employer owes him Rs 1,30,963.

It took Kumar two-and-a-half years to get back to earning a livelihood; just a month ago, he began plying a rickshaw. “I can’t hold anything, it hurts too much. My employer threw me out soon after because I was of no use to him… When I looked for work, factory owners either rejected me or offered to pay half. How is this not a full-fledged disability?” he said.

IFTU’s Rajesh Kumar, who has a stronghold in Mayapuri industrial area as a trade union leader and is pursuing Kumar’s case in the labour court, said, “The problem lies with the percentage of disability granted to those who lose fingers… It’s considered a small injury but in reality, it renders many labourers useless because they are unskilled.”

The cover-up

An hour away in Azadpur village, Savita is known in her colony as “the woman with two missing fingers, seven children and a court case”. On September 6, 2016, the 45-year-old lost two fingers of her left hand to the power press machine at a factory where she had worked for two years.

“We made steel utensils. The machine operator was on leave, so I was asked to step in, without proper training… I fainted due to the pain and woke up in a private clinic, where a nurse gave me first-aid, stitches and medicines. The employer didn’t give me prescription papers or any proof of the visit to the clinic,” said Savita.

Savita, who lost two fingers to the power press machine.(Express photo/Tashi Tobgyal)

Savita, who lost two fingers to the power press machine.(Express photo/Tashi Tobgyal)

A few days later, Savita, who worked 11 hours a day and made Rs 10,000 a month, was fired. “There is a court case going on,” said Savita, who approached the labour welfare office.

Eight labourers The Indian Express spoke to in Wazirpur industrial area and Azadpur said that instead of being taken to a hospital, they were taken to private clinics. “Many employers send injured labourers to a clinic in Ashok Vihar… vahan deal hai, koi jhanjhat nahi hai (there’s no issue there). I’ve been instructed not to give them discharge papers or any document that proves they were admitted with a work injury,” said a man responsible for handing out wages to workers at a steel unit in Wazirpur.

Another problem, IFTU and Delhi Ispat (steel) Udyog Mazdoor Union members said, is that many workers don’t have Employees’ State Insurance (ESI). Rajesh Kumar from IFTU said, “As per the ESI Act, an employer is supposed to provide ESI cards if the unit has 10 or more workers and uses power… if it doesn’t use power and there are 20 employees, then, too, they are supposed to get ESI cards. But employers usually don’t want that because that guarantees a certain wage, leaves and pension. It gives a worker permanent employee status.”

‘Gross negligence’

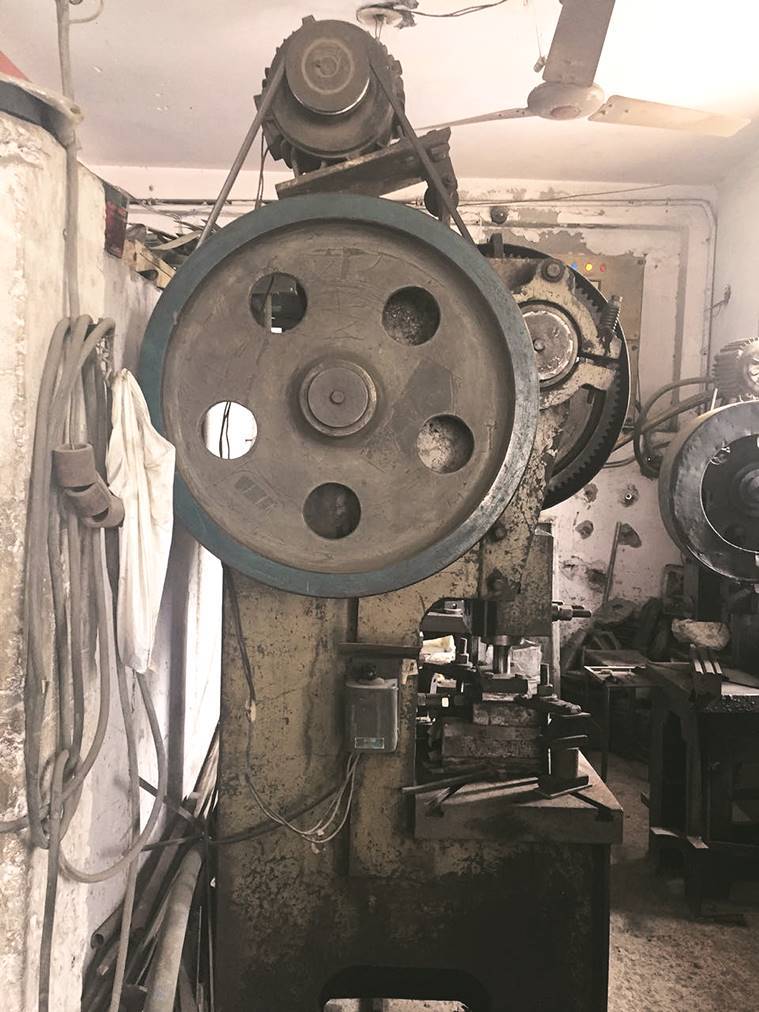

In Mayapuri, a hub of cardboard cutting, iron cutting and plastic products, heavy machines run almost non-stop. The Indian Express visited two units here — one with two shearing machines, used to cut iron slabs, and another with the infamous power press machine, used to punch holes in iron and steel blocks. There are also units that have injection moulding machines to make plastic products.

“The probability of one’s hand coming under the heavy, round part that punches holes is high… I have been at this factory for a decade, and this machine has never been taken out for maintenance. Nor do labour inspectors check if they work properly or should be discarded,” said a worker at one factory.

About 15 minutes away, at the emergency ward of ESI Hospital in Basai Darapur, Dinesh Pal Singh (50) bears testimony to the perils of using such machines without precaution. With a bandaged left hand and an external fixator keeping his two fingers together, he sits with his daughter, Mona (25).

“The unit he works at make sieves for flour… there is gross negligence in his case. The power press machine didn’t work properly and his fingers got cut on Friday. He has an ESI card so he was brought to the hospital; then police came and took his statement. We just want his fingers to be saved; we will think about compensation later… But I don’t want him to return to that factory,” she said.

Singh earned Rs 10,000 per month, 1.75% of which was cut for ESI. “We wouldn’t have been able to afford the surgery if it wasn’t for the ESI,” his wife said. The external fixator will come off after two months.

While a senior orthopaedic surgeon at the hospital claimed that he has seen only one patient a month with severed fingers, the emergency ward told a different story. A doctor there said, “We get three-five cases of chopped or crushed fingers every week… In many cases, carpal and metacarpal bones get fractured and are fixed by inserting K-wires. In other cases, amputation is required.”

He added: “They are all labourers operating heavy machinery. You end up losing movement, you can’t do basic things like holding a mug, so getting back to the job is obviously out of the question.”

28 industrial areas in the capital

– Mayapuri: Known for production of plastic items, cardboard cartons, machines parts

– Wazirpur: Stainless steel utensils, iron rods, iron doors

– Karawal Nagar: Denims and parts of a shirt like sleeves, collar and cuffs

– Okhla: Clothes and cardboard cartons

– Bawana: Plastic items and denims

– Naraina: Clothes, cardboard cartons

– Kirti Nagar: Wooden furniture

– Mongolpuri: Shoes

– Sultanpuri: Shoes

– Peera Garhi: Shoes

– Anand Parbat: Machine parts

– Patparganj: Glass bangles, stainless steel utensils, fire crackers

– Narela: Plastic items, cardboard cartons, denims, shoes

The most common machines

– Shearing machine: Has blades or rotary disks used to cut metal sheets, plates or bars

– Power press machine (above): Used to bend sheet metal into a specific shape

– Injection moulding machine: Used to make plastic items by injecting molten material into a mould

Disability percentage as per Employees’ Compensation Act 1923

– Loss of a hand and a foot 100%

– Amputation through shoulder joint 90%

– Loss of a hand or the thumb and four fingers of one hand 60%

– Loss of thumb 30%

– Loss of four fingers of one hand 50%

– Loss of three fingers of one hand 30%

– Loss of two fingers of one hand 20%

– Amputation of both feet resulting in end bearing stumps 90%

– Loss of all toes of one foot 20%

Apr 18: Latest News

- 01

- 02

- 03

- 04

- 05