Carbon emission across the world has increased exponentially in the past decades. In the year 2019, the global energy-related CO2 emission was 33 Gigatons, which includes the power sector, transportation, and industrial emissions. While it might take some time to develop vehicles with zero carbon emissions, electric vehicles are certainly one of the greener alternatives with fewer lifecycle emissions.

Electric Vehicles have been a key discussion point in the automotive industry and governments across the world over the last few years. India launched schemes like FAME I, FAME II, and various tax sops to promote electric vehicles in India. However, when we talk about EVs, we usually think of batteries and powertrain only. EVs means a rehaul of an entire ecosystem and architecture of a vehicle and the surrounding environment. All power sources are primarily battery-driven, which makes it critical to have efficient, smart systems within a vehicle and externally.

This means we have to explore how other aspects of a vehicle are also changing to adapt to EVs and the new environment.

Brake Systems

At the early stages of the evolution of cars, the vehicles were slowed down by pulling a lever attached to cables and were very difficult to control. In 1914, Fred Duesenberg developed the first hydraulically operated system, which upgraded the system. Since that, the brakes have evolved considerably, especially after electronic components entered vehicles.

In the EV ecosystem, there are several critical issues to be addressed while designing a brake system, including but not limited to how the system will work with the other components. The technology should also be energy-efficient and help in reducing emissions; this is where a dynamic recuperative feature adds a great value, which can be fulfilled by brake-by-wire systems.

The “One-Box Brake-By-Wire Solution” aims to enable full utilisation of the recuperation potential. Several functionalities are coupled to make this brake-by-wire solution more space-efficient and energy-efficient. This allows the vehicle to recover more electricity and achieve measurable CO2 savings. The ‘One-Box’ system integrates the brake actuation, the brake booster, and the control systems into a single, compact, and weight-saving module. They also help in reducing carbon emissions. If we take an example of the MKC1 solution, it helps reduce CO2 emissions of hybrid electric vehicles by around 5 g/km and also extends the electric range of all battery-powered vehicles with savings of around 30 percent regenerative energy.

Human Machine Interface (HMI)

Vehicles today have evolved beyond mere transportation modes. They are personal devices, where comfort is as important as safety to a consumer. Therefore, HMI technologies become crucial to facilitate the same. In electrified vehicles, HMI technologies can play an essential role in communicating critical data related to energy management, battery optimisation, and other information to the driver.

With electrification opening doors for more technologies, the vehicles would need High-Performance Computers (HPC). HPC systems can solve complex problems by pooling the computing power of multiple nodes in parallel. HPC reduces the dependence on numerous classic electronic control units, sensors, and actuators. Thus, it offers an enhanced and more streamlined functionality.

HPC also offers a much higher degree of flexibility regarding the development of cockpit systems. Such flexible solutions are crucial for future developments to meet both the trend toward centralized vehicle architecture as well as increasing software complexity along with the rapidly growing range of functions in the cockpit. On the other hand, HPC could support in keeping the digital network of the vehicle up-to-date and even secure it from potential cyber threats, by enabling OTA (over-the-air) functionality.

For an EV, vehicle light-weighting is a crucial factor in achieving better range and handling. Considering this, the systems within the vehicle needs to be optimized to offer integrated functionality and overlook the conventional system. For instance, Ac2ated Speakerless Audio Systems is an innovative concept abandons traditional technology of speakers altogether, exciting select surfaces in the vehicle interior to produce sound. With Ac2ated Sound, carmakers can reduce the weight of a sound system by up to 75-90 percent.

V2X

The future of mobility is electric, and connectivity is essential for it. EVs will utilize V2X connectivity just like other vehicles – and more. While the road-safety and comfort benefits of seamless connectivity apply to all vehicles, added efficiency, and range are the additional benefits for the EVs.

5G, in combination with V2V, facilitates a seamless communications experience from long range to short range. The cars no longer need to have only short-range, immediate warnings, and long-range traffic alerts. Still, safety risks can be tracked from longer distances. Allowing the vehicle, and driver, to be notified in a much timelier manner, enabling safer, more comfortable human-level reaction times rather than having to trigger a rapid decision to either brake or swerve.

5G cellular networks help in closing the performance gap between V2N (vehicle-to-network) and V2V (vehicle to vehicle) and thus facilitating a seamless communications experience from

long range to short range. This seamless communication helps EVs to run for longer distances with minimum interruptions. For instance, if the driver gathers info through seamless networking (i.e., access to timely, relevant information), the average traffic flow speed, and when the oncoming traffic light will turn green, they can adjust the driving speed accordingly, or a signal-change advisory can be triggered. The same applies to a situation where the driver is informed in time about an approaching vehicle with priority. Moreover, in a typical scenario, EV range anxiety can also be eased through real-time range calculation and suggestions on an optimally located charging station.

Telematics

There are various challenges that a fleet has to overcome to utilize the benefits of EVs. A few of the challenges are putting vehicles into use without knowing their state-of-charge, making drivers responsible for determining when and where to charge, scheduling charging for less-than-optimised times, charging vehicles longer than necessary at public stations, etc.

Telematics systems enable communication between a network and a vehicle, aiming to solve these issues with effective route management, energy and charge reporting, GPS vehicle tracking, and battery health monitoring, along with all the other aspects of the equation.

Cybersecurity in EVs

Electric vehicles are also bound to be smart vehicles. The entry of the internet into the car, while enables many safety and comfort features, also leaves it open to hacks and other threats. We could be looking at a future where a hacker can remotely drain a battery, or the steering control could be taken over. As cars become IoT devices, we also have to think about data protection.

There is a crucial need to develop means based on artificial intelligence and machine learning to fight cyber-attacks and minimize its impact on the IoEV framework. Automotive cloud security could help stakeholders by giving them an entire picture of the data flows in their surroundings. It makes it easy for users to identify threats to one’s network and identify deviation beforehand.

Tyre Pressure Monitoring System

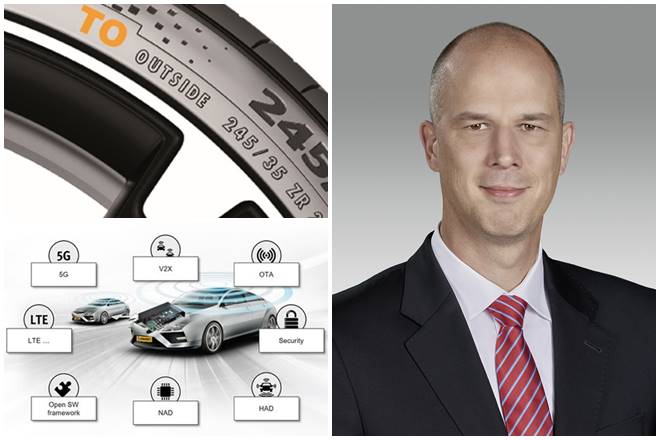

The optimal tyre pressure is critical in maintaining the EV range. The Tyre Pressure Monitoring System (TPMS) measures the pressure inside a tyre directly, transmits the reading, and displays it. The driver is alerted of a critical situation using a corresponding signal. The TPMS takes the reading directly on the wheel. Battery-fed sensors mounted on the rim and integrated into the valve measure the tyre’s inflation pressure and send a high-frequency signal with coded information to a receiver. Special software in the control device then processes the data received and shows it on the display of the instrument panel.

Also read: Continental Transparent Hood: Car safety feature that allows driver to see through bonnet

Intelligent Battery Sensor (IBS)

In a case of hybrid vehicles like the 48V technology that can be implemented in both gasoline and diesel engine cars, the need for a 12-Volt lead-acid battery persists as a backup during the cold conditions. IBS continuously analyzes the status of conventional 12-Volt lead-acid batteries and provides information on such critical parameters as the state-of-charge, state-of-function (power ability), and state-of-health (aging) of the battery. The sensor thus makes up for the reliable operation of automotive start-stop systems. The IBS is mounted directly onto the battery and fits exactly into the niche around the negative terminal. This means that it can be deployed with any standard battery. The sensor enhances the automobile’s diagnostic ability and can thus warn of possible breakdowns that may not even be caused by the battery. Moreover, the IBS helps to extend battery life by 10 to 20 percent via an improved charging strategy.

Tyres

The type of tyre holds a vital place in contributing to EV’s performance. Today the market offers multiple tyre options that are specifically designed for EVs. For instance, one of the 20-inch tyres for electric vehicles delivers rolling resistance that is an impressive 30 percent or so lower than that of a conventional tyre. Another variation of the tyre for hybrids offers 20 percent less rolling resistance.

As we begin the transition towards EV systems, there are more such components of a vehicle that will undergo a massive evolution. HMI, brakes, telematics, tyres, TPMS, IBS, connectivity, and cybersecurity are few of the many technologies that are crucial in the development of an electric vehicle. In other words, electrification beyond engines is as crucial as electrification of the engine.

Author: Alexander Klotz, Head of Technical Center India, Continental Automotive India

Disclaimer: The views and opinions expressed in this article are solely those of the original author. These views and opinions do not represent those of The Indian Express Group or its employees.