Trending

This story is from October 20, 2020

Pune-based sanitary pad incinerator finds acceptance in colleges, hospitals

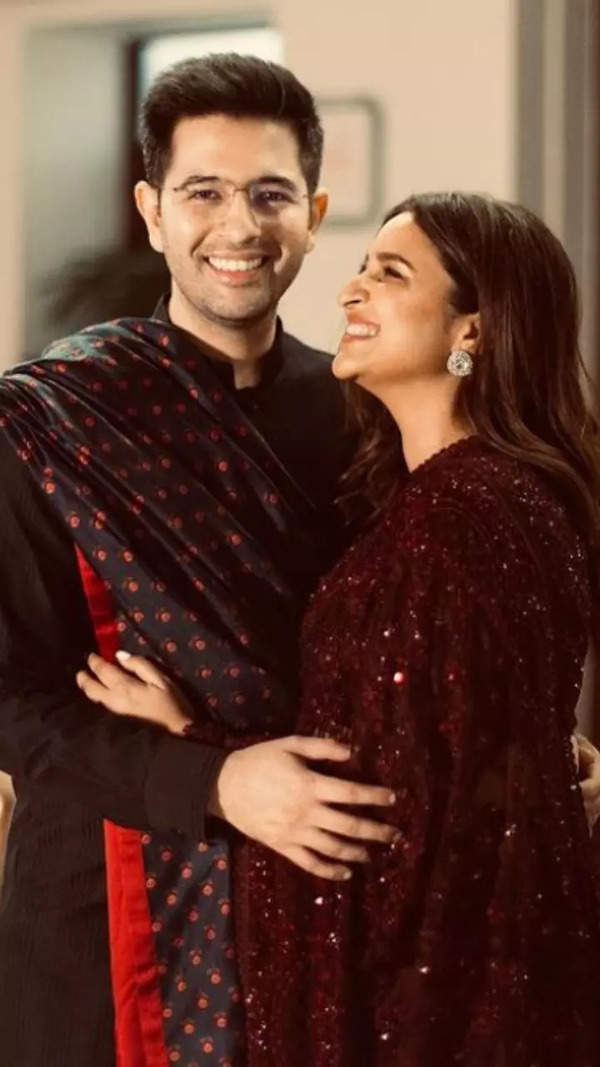

Pune-based year-and-a-half old start-up, GJ Lustre, has designed, developed and deployed over 600 sanitary pad incinerators across four places, while also turning profitable in a short period of time.

GJ Lustre has designed, developed and deployed over 600 sanitary pad incinerators across four places

PUNE: Pune-based year-and-a-half old start-up, GJ Lustre, has designed, developed and deployed over 600 sanitary pad incinerators across four places, while also turning profitable in a short period of time.

The company founded by engineering students, Diksha Gokhale and her colleagues had its genesis in the overflowing bins filled with pads in the all women college they passed out of.

“It was heart wrenching to see tai (domestic staff) clean it up. We wanted to do something and so thought of this. The machine turns pads into ash in a matter of minutes and is also less expensive to dispose due to reduced weight,” she said.

In one year, since the product got approval, the incinerator is finding acceptance across colleges, hospitals and some self help group societies in Pune, Jalgaon, Mumbai and Gujarat.

Incinerator techniques to dispose refuse is not entirely new. In fact, Gokhale and her team got this idea during one of the chance visits to a place where the Pune Municipal Corporation runs a huge incinerator.

“We thought we can apply the same solution but then improvised on it. There are a lot of sanitary pad vending machines in the country. In many schools, the right way to use pads is also taught but no one teaches how to dispose a pad safely. So, that is the problem we took to solve,” Gokhale told TOI.

The difference between burning the napkin and incinerating it is in the scientific process of the latter, i.e. it is done in consonance with state pollution norms.

She said that it took about eight months for the company to break-even. And now it is at a stage where they are able to pay their rents for the factory and also make some money for the team.

“It is not a lot, but we are growing,” she said.

In a meeting with various hospital authorities, she said that the team was acquainted that some amount per bag or per kilogram weight of waste has to be paid by the hospital to the waste management company or the corporation.

“So, 100 napkins soaked definitely weighs more than 100 napkins turned into ash,” she said.

Going forward, the company is looking to use recyclable materials for its solutions and also scale up its manufacturing to deploy more machines. In addition, the team at GJ Lustre has come up with various designs and models of Sanitary Napkin Vending Machine.

However, before starting their venture, Gokhale and her team worked in several jobs for a year on insistence from parents, which she said was a “wise decision” as it helped them with experience and money both.

The company founded by engineering students, Diksha Gokhale and her colleagues had its genesis in the overflowing bins filled with pads in the all women college they passed out of.

“It was heart wrenching to see tai (domestic staff) clean it up. We wanted to do something and so thought of this. The machine turns pads into ash in a matter of minutes and is also less expensive to dispose due to reduced weight,” she said.

In one year, since the product got approval, the incinerator is finding acceptance across colleges, hospitals and some self help group societies in Pune, Jalgaon, Mumbai and Gujarat.

“The weight reduction achieved or the residue ash is one gram per napkin. The machine that burns 100 napkins a day requires four minutes to burn 10-12 napkins together,” Gokhale added.

Incinerator techniques to dispose refuse is not entirely new. In fact, Gokhale and her team got this idea during one of the chance visits to a place where the Pune Municipal Corporation runs a huge incinerator.

“We thought we can apply the same solution but then improvised on it. There are a lot of sanitary pad vending machines in the country. In many schools, the right way to use pads is also taught but no one teaches how to dispose a pad safely. So, that is the problem we took to solve,” Gokhale told TOI.

The difference between burning the napkin and incinerating it is in the scientific process of the latter, i.e. it is done in consonance with state pollution norms.

She said that it took about eight months for the company to break-even. And now it is at a stage where they are able to pay their rents for the factory and also make some money for the team.

“It is not a lot, but we are growing,” she said.

In a meeting with various hospital authorities, she said that the team was acquainted that some amount per bag or per kilogram weight of waste has to be paid by the hospital to the waste management company or the corporation.

“So, 100 napkins soaked definitely weighs more than 100 napkins turned into ash,” she said.

Going forward, the company is looking to use recyclable materials for its solutions and also scale up its manufacturing to deploy more machines. In addition, the team at GJ Lustre has come up with various designs and models of Sanitary Napkin Vending Machine.

However, before starting their venture, Gokhale and her team worked in several jobs for a year on insistence from parents, which she said was a “wise decision” as it helped them with experience and money both.

End of Article

FOLLOW US ON SOCIAL MEDIA