Will perovskite solar cells provide answer to Korea’s carbon neutrality?

Next-generation solar cells emerge as key element for Korea’s zero-energy building plans

By Kim Byung-wookPublished : Dec. 26, 2020 - 15:01

Starting in 2030, all new buildings in South Korea, public or private, with a gross floor area of 500 square meters or more must be fully energy efficient, generating the power they need from renewable sources such as the sun, wind and water.

Part of the country’s grand plan to go carbon neutral by 2050, the zero-energy building rule is widely expected to boost local demand for solar panels for building walls.

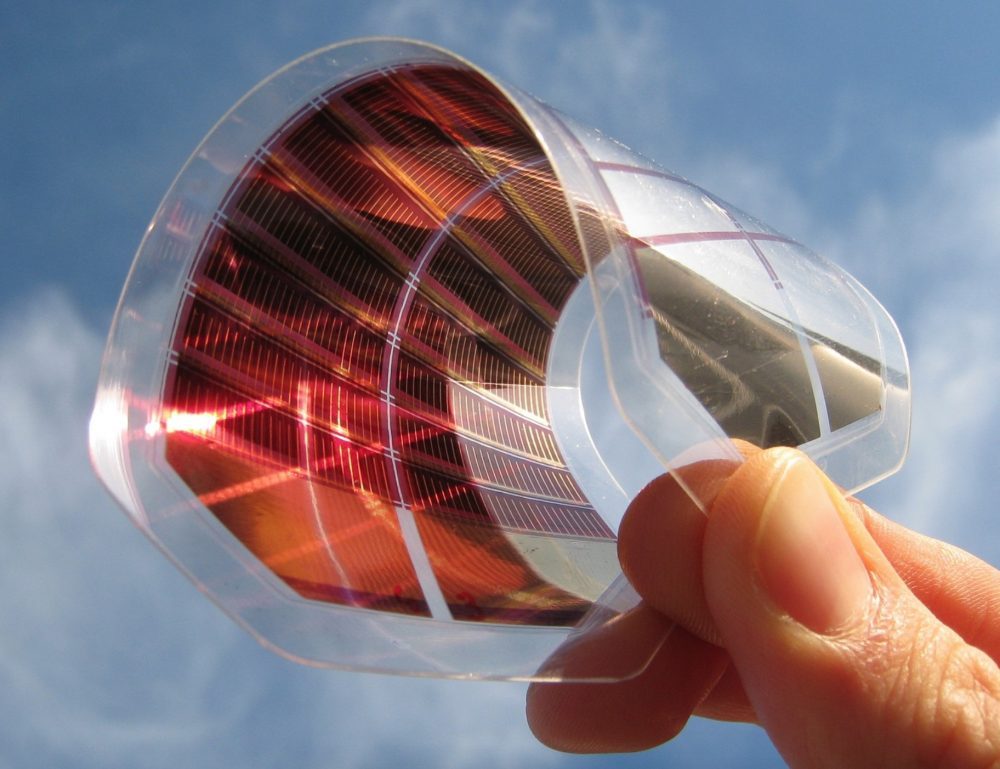

Next-generation solar cells made from materials called perovskites are drawing attention for their potential to revolutionize the solar industry, greatly aiding the country’s ambitions for green buildings.

What are perovskites?

Most solar panels installed on building rooftops and vacant lots are slabs of crystalline silicon. Compared to them, perovskite-based solar cells have the potential to improve the economics of building installations. Efficiency and price are two core strengths of the new material.

“Solar panels must receive sunlight at a direct angle, or their performance drops significantly. However, perovskite solar cells can maintain their performance in much wider angles, even with sunlight coming at 10 degrees, making them eligible for installing on building walls,” said Seok Sang-il, a professor of energy and chemical engineering at Ulsan National Institute of Science and Technology, who developed the perovskite solar cell with the highest efficiency rate in the world of 25.17 percent, as of October. The efficiency rate indicates the proportion of solar energy converted into usable energy.

“Government’s plan to seek carbon neutrality through zero-energy buildings seems like a great idea as it can address various (environmental) issues of installing solar panels on land,” the professor added.

Perovskites are easily synthesized compounds with an orthorhombic crystal structure. Perovskite solar cells exploit micrometer-thin films made of these materials to harvest light.

“Compared to silicon-based solar cells, which took 40 years to improve their efficiency rate to the current level of 27 percent from 15 percent since 1980, it took less than 10 years for perovskite solar cells to boost their efficiency rate to the current 25 percent from 12 percent in early 2010s,” Hyundai Motor Securities analyst Kang Dong-jin.

The analyst added that perovskite solar cells, though 100 times to 200 times thinner than silicon-based solar cells, can absorb the same amount of sunlight, making them light and flexible. In terms of the manufacturing process, silicon-based solar cells require higher temperatures -- above 1,000 degrees Celsius -- while perovskite solar cells can be manufactured at between 150 and 200 degrees Celsius, which translates into a significant cut in manufacturing costs.

Cloudy market condition

The reason perovskite solar cells haven’t been commercialized yet is because key technological issues haven’t been solved.

“Perovskite solar cells are susceptible to moisture and heat, but efforts are being made to tackle the weaknesses by synthetizing perovskites with different compounds, though there is a trade-off of lower efficiency rate,” Heungkuk Securities analyst Chun Woo-je said.

According to professor Seok, such challenges are likely to be addressed in three to four years, as extensive research is underway globally, with more than 3,000 papers regarding perovskite solar cells pouring out annually.

However, even if such challenges are solved, introducing perovskite solar cells to building owners here could be a completely different story.

“We have held meetings with many companies interested in our perovskite materials, but actual investments haven’t been made. Korean companies hesitate because if they launch a perovskite materials business, they will ultimately have to compete against Chinese companies in terms of price competitiveness,” professor Seok said.

From 2018 to 2020, three major Korean manufacturers of polysilicon -- OCI, Hanwha and Hankook Silicon -- gave up or suspended their polysilicon businesses for solar cells in a game of chicken with Chinese firms that created an oversupply of raw materials. This has left a precedent for Korean companies that manufacturing raw materials of solar cells is a losing game, including perovskite materials, the professor explained.

The price of polysilicon, which stood at $400 per kilogram in 2008, had plummeted to $14.50 in 2015 and plunged further to $10.40 in 2018. Last year, the price dropped even more, to $8.40. In February, the price stood at $7.10, according to PV InfoLink data.

Also, it remains to be seen whether Korea’s lead in perovskite technology will actually guarantee a lead in the marketplace.

“Even right now, Korean solar power companies have a technological edge over Chinese companies, but Chinese companies are dominating the global market with their size. There is no guarantee that the same will not happen to the future perovskite solar cell market,” the professor added.

According to the Export-Import Bank of Korea, China commanded 64 percent, 92 percent, 85 percent and 80 percent of the global polysilicon, ingot and wafer, cell and module markets, respectively, as of 2018.

Taking the middle road

As jumping straight into the perovskite business poses complicated risks, major Korean solar power companies such as Hanwha Q Cells are developing tandem cells, a hybrid of conventional solar cells and perovskite solar cells.

When a layer of perovskite is placed on top of a silicon solar cell, it becomes a tandem solar cell. While perovskite solar cells absorb a shorter wavelength of blue light, silicon-based ones absorb a longer wavelength of red light. This difference in absorption depth allows tandem cells to maximize its efficiency rate.

“In theory, silicon-based solar cells’ maximum efficiency rate is 29 percent. However, tandem cells can achieve up to 44 percent,” a Hanwha Q Cells official said. Hanwha Q Cells, which stood as the world’s sixth leading solar module manufacturer by shipments as of last year, aims to mass produce tandem cells starting 2023 or 2024.

As to why Hanwha plans to manufacture hybrid tandem solar cells, but not independent perovskite solar cells which are theoretically thinner and cheaper, the official pointed to the tiny domestic market.

“The government’s incentives for zero-energy buildings only apply to “new” buildings. Also, the exact standards of perovskite solar cells haven’t been decided yet, meaning that we can’t predict at the moment which type or size of products construction companies will need in the future,” the official said.

As the commercialization of perovskite solar cells is expected to take several years, Shinsung E&G, another Korean solar power company currently developing tandem cells, has introduced silicon-based solar panels with different colors to go along with the color of the building.

“Starting this year, all new public buildings must become zero-energy buildings. Starting 2025, all new private buildings must be built as zero-energy buildings. For this reason, the demand for Shinsung E&G’s ‘solar skin’ panels has spiked, as they can harmonize with the exterior of a building with the same color. Also, solar skin panels have matt surfaces, minimizing the reflection of light,” a company official said.

By Kim Byung-wook (kbw@heraldcorp.com)