Manufacturing: An Attractive Target for Cybercriminals

According to the World Economic Forum, cybercrime is the world’s third-largest economy after the US and China. Its profit outpaces global drug trafficking, counterfeiting and human trafficking combined. The primary motivation for cybercrime is financial gain, so they direct their operations and attention to the sectors where they stand to make the most profit.

Manufacturing has in recent years been their biggest target.

In 2023, the industry bore the brunt of ransomware attacks, accounting for 17.2% of all attacks recorded in the UK according to Palo Alto. IBM’s 2024 X-force threat intelligence index reported that when it comes to cyber attacks manufacturing was the most targeted industry in Europe, accounting for 28% of cases. This raises major concerns about the industry’s ability to safeguard its operations and vital assets in addition to questions about why it’s such a major target.

Why do cybercriminals target supply chain manufacturing?

The manufacturing sector is transforming.

Digitising factories, systems and supply chains is a comprehensive process that in the realm of cybersecurity functions as a double-edged sword. It’s led to increased growth, profitability and efficiency but has also exposed the industry’s vulnerabilities to hostile forces eager to exploit them.

Multiple factors, like a lack of unified cybersecurity standards across nations and companies along with a digital skills gap in the workforce, have contributed to the sector’s vulnerability to cyber crime.

To avoid disruption and financial losses, manufacturers need to address their vulnerabilities and shore up their cybersecurity. They must meet the growing complexity of cyber-physical systems by enhancing their security infrastructure. To defend the manufacturing sector against cyber threats, a comprehensive approach is needed that addresses the existing vulnerabilities of the industry.

Here are four major areas that must be covered:

- Collaboration and information sharing: Industry leaders should collaborate and share information on emerging threats and effective defence strategies.

- Risk management and response planning: Companies should develop and maintain a comprehensive risk management plan and a well-defined incident response strategy.

- Employee training and awareness: Regular training and awareness programs should be conducted to educate employees on the importance of cybersecurity and how to recognise and respond to potential threats.

- Implement robust cybersecurity measures: Companies must invest in state-of-the-art cybersecurity infrastructure and adopt best practices to protect their assets and operations.

As the manufacturing sector embraces Industry 4.0, robust cybersecurity measures are urgently needed. By taking a proactive approach and understanding the challenges they face, industry leaders can build a more resilient and secure manufacturing ecosystem. They can better protect their valuable assets and operations, maintaining the ongoing growth and success of the industry. A security-focused mindset must become the norm in manufacturing. A mindset that doesn’t say “what if?” but when.

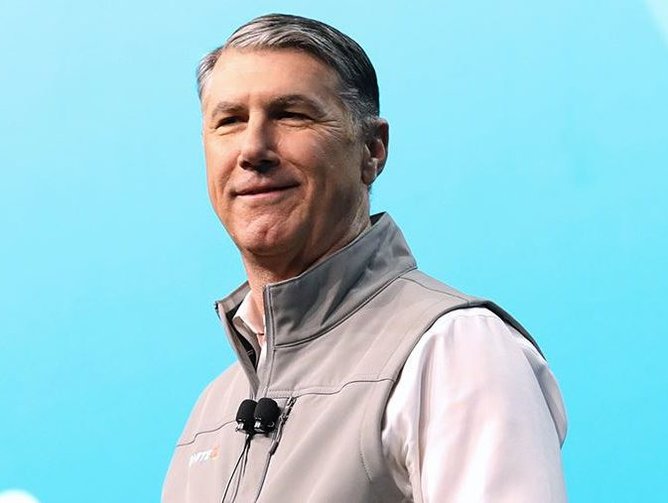

"The speed and scale of threats are accelerating, with many attackers exfiltrating data in less than 24 hours from the initial compromise of an organization," said BJ Jenkins, President of Palo Alto Networks, while publicising the company's partnership with IBM. "Organizations today need the right cybersecurity partners to keep up with the pace of the ever-changing threat landscape.

Manufacturers need to operate with the mindset that an attack is constantly on the horizon- because in all likelihood it is. Enhancing their employee training, investing in cyber security infrastructure and implementing stringent operational policies are crucial to ensuring manufacturers stay protected.

******

Make sure you check out the latest edition of Manufacturing Digital and also sign up to our global conference series - Procurement & Supply Chain 2024 & Sustainability LIVE 2024

******

Manufacturing Digital is a BizClik brand.

- Verizon: Increase in Error-Related Breaches in ManufacturingProduction & Operations

- Normative: Carbon-reduction in Supply Chain ManufacturingSustainability & ESG

- Capgemini: UK Manufacturing and ReindustrialisationProduction & Operations

- Dassault Systèmes Bring AR Manufacturing Showcase to LondonSmart Manufacturing